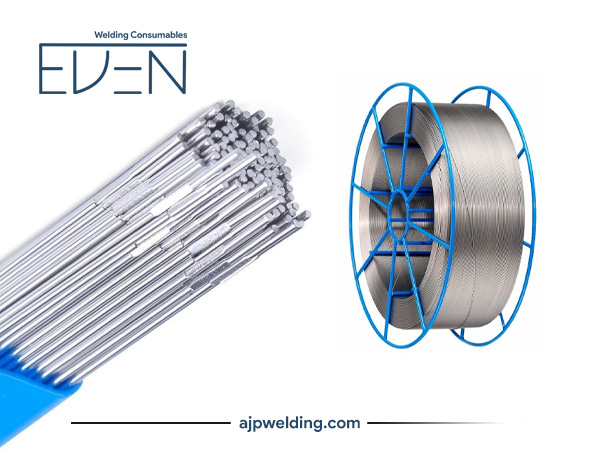

SUPER MIG 2594 is a G 25 9 4 N L type solid MIG welding wire, supplied precision layer wound, depositing a C-25Cr10Ni4Mo weld metal suitable for use with Ar+2%O2 or Ar+0.5…5%CO2 mixed shielding gases.

SUPER MIG 2594 is used for the welding of Super-Duplex stainless steels, mainly used in Offshore applications, paper industry, oil industry and artificial manure production.

It is often used for root pass welding of 22%Cr standard duplex steels for critical applications, also for the welding of low carbon super martensitic 13%Cr steels. SUPER MIG 2594 has a very good resistance to general corrosion, the weld metal has a high resistance to pitting combined with a good resistance to crevice corrosion as well as stress corrosion cracking.

The nickel over matches the parent material by 2-3% to provide an optimum balance of austenite and ferrite in the as welded condition.

SUPERTIG 2594 is a W 25 9 4 N L type solid TIG welding rod depositing a C-25Cr 10Ni 4Mo weld metal suitable for use mainly with Ar shielding gas.

SUPERTIG 2594 is used for the welding of super-duplex stainless steels. Mainly used in offshore applications, paper industry, oil industry and in the production of artificial manure.

Used for root pass welding of 22%Cr standard duplex steels for critical applications, and for the welding of low carbon super martensitic 13%Cr steels.

Features

ER 2594 is a super duplex welding wire. Super Duplex Steel ER 2594 Filler wire provides matching chemistry and mechanical property characteristics to wrought super duplex alloys such as 2507 and Zeron 100 as well as super duplex casting alloys (ASTM A890). Super Duplex Steel ER 2594 welding wire is over alloyed 2-3 per cent in Nickel to provide optimum ferrite/austenite ratio in the finished weld. This structure results in high tensile and yield strength along with superior resistance to SCC and pitting corrosion.

The welding wire is over-alloyed with nickel compared to the base material to ensure the optimum combination of microstructure, mechanical properties and corrosion resistance. The wire has additions of Cu and W which provides enhanced corrosion resistance to sulphuric and hydrochloric acids.

The super duplex stainless steel base materials have a microstructure consisting of nominally 50% austenite in a ferrite matrix. Normal service temperature range is -50 degree.

Applications

Arcos 2594 is utilized for welding in the chemical and fertilizer industries, energy generation, flue gas desulfurization and for many offshore applications including piping systems, pumps, valves and heat exchangers.

⚠️Caution

Protect yourself and others read the safety data sheet prior to using this product.