Working with thinner sheets of metal is tricky. If you use too much heat, you may end up with a burn-through. Too little may result in not enough weld penetration and will produce brittle joints.

The welding process you choose plays a critical role in the success of the procedure. If you want to know how to weld thin metal, then keep on reading. To ensure a successful joint when working with thin gauge material, you need to keep a few things in mind.

Minimizing Burn Through

A burn-through occurs when the molten weld pool collapses, dismembering itself from the workpiece. The result is a large hole instead of a perfect joint. The defect arises due to high-temperature inputs and is impossible to workaround. The welder will then have to start again on a new workpiece.

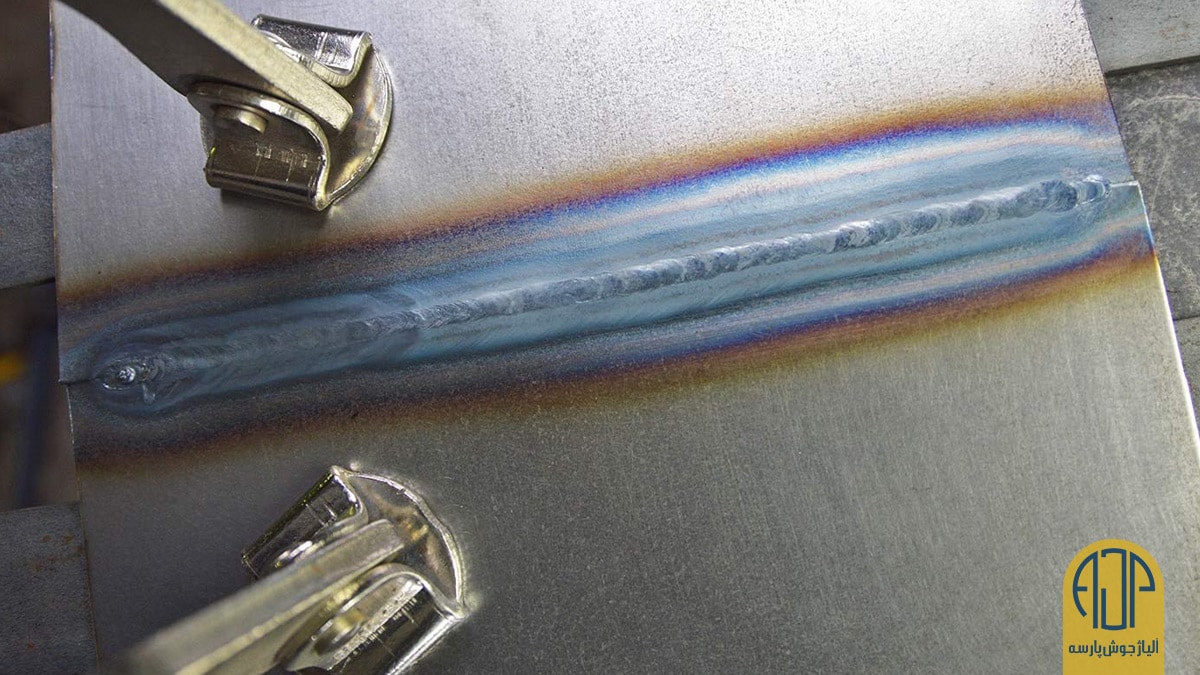

Weld Bead Appearance

Because thin-gauge metals warrant the use of lower heat inputs, the weld bead appearance may produce a higher amount of spatter. Welders usually face this problem when working with stainless steel filler metals.

Torch Angle

The placement of the torch significantly impacts the amount of energy transfer. You need to take into account the properties of the metal and its melting point when deciding on the working angle and travel speed. All these factors impact the amount of energy the metal is exposed to at one time. It can either increase or reduce the risk of a burn-through.

Shield Gas

Your choice of gas significantly affects the productivity rate of the process. If it does not transfer energy as effectively as it should, it could produce weak quality joints. If it has incredibly high energy transfer rates, it will create a significant amount of spatter, and you also run the risk of blowing through the material.

You can use either the tungsten Inert Gas (TIG) or Metal Inert Gas (MIG) welding procedure for these types of joints.

Metal Inert Gas for Thin Sheets

Gas Metal Arc or Metal Inert Gas welding is the most commonly used welding procedure for metal sheets. Depending upon the weld type and the size of the sheet, you can use either the regular MIG welding technique or combine it with the pulsing method to avoid a blow through.

Pulsing

In this method, you heat a small segment of the plates that are to be joined and then allow the weld pool to cool completely. You should not attempt to fill in the join all at once as it can create a hole in the workpiece instead.

The process has high material penetration and metal deposition rates. The intense energy exposure in this technique warrants extra care when working with brittle material. To control the amount of risk, always use the shortest wire diameter in the process. It takes less energy to melt, which limits the amount of heat transfer to the base metal.

A significant reason why this method is so widely employed when working with sheet materials is the control it allows over the energy input. It also allows for better control over the weld bead appearance, which makes it easier to fix mistakes that may arise due to lower deposition rates.

Tips and Tricks:

- Never use a filler wire with a diameter that’s more significant than the thickness of the base material

- For mild steel, use an ER70S-6 cable as per the American Welders Association Classification. It has a broader wetting coverage and maximizes the contact area.

- Use a shielding gas with a high argon percentage – it transfers less heat than pure carbon dioxide does.

- Use a Direct Current Electrode Positive polarity. It releases more heat towards the metal wire and less toward the base metal.

- Using a Direct Current Electrode Negative can be dangerous and counterproductive. It passes on less heat to the filler wire and more to the base material. You may end up overheating the workpiece and not have enough filler deposit to form the joint.